What is Plum Concrete and Its Applications

- By

- Pooja |

- January 22, 2023 |

- Civil Engineering, Innovation, Building/ Structure Engineering,

Table of Contents

Specification of Plum Concrete

Construction Procedure of Plum Concrete

What is Plum Concrete?

To create plum concrete, stones up to 300mm in size are typically used as filler. With this technique, less cement can be used without sacrificing strength, increasing the apparent yield of concrete. Plums are the common name for the huge stones used. These plums go towards building mass concrete.

Plums can provide flavour but don't make up more than 30–40% of the total volume of the concrete when mixed in. In addition to its more common names, plum concrete is also sometimes called cyclopean concrete or rubble concrete. The Plum's diameter must be no more than one-third of the mixer's cross-section.

It is recommended that 60% plain concrete along with 40% big stones be used in the making of Cyclopean concrete according to the United States Technical Specifications. For this project, you'll need plain concrete with a minimum 28-day resistance of 180 kg/cm2, and all of your ingredients should be thoroughly saturated before you begin mixing. The stone used must align with ASTM standards, and its exact dimensions will be decided by the blueprint for the concrete.

Specification of Plum Concrete

According to General Specifications (40 1.3.6.f), the following are the design requirements for plum concrete:

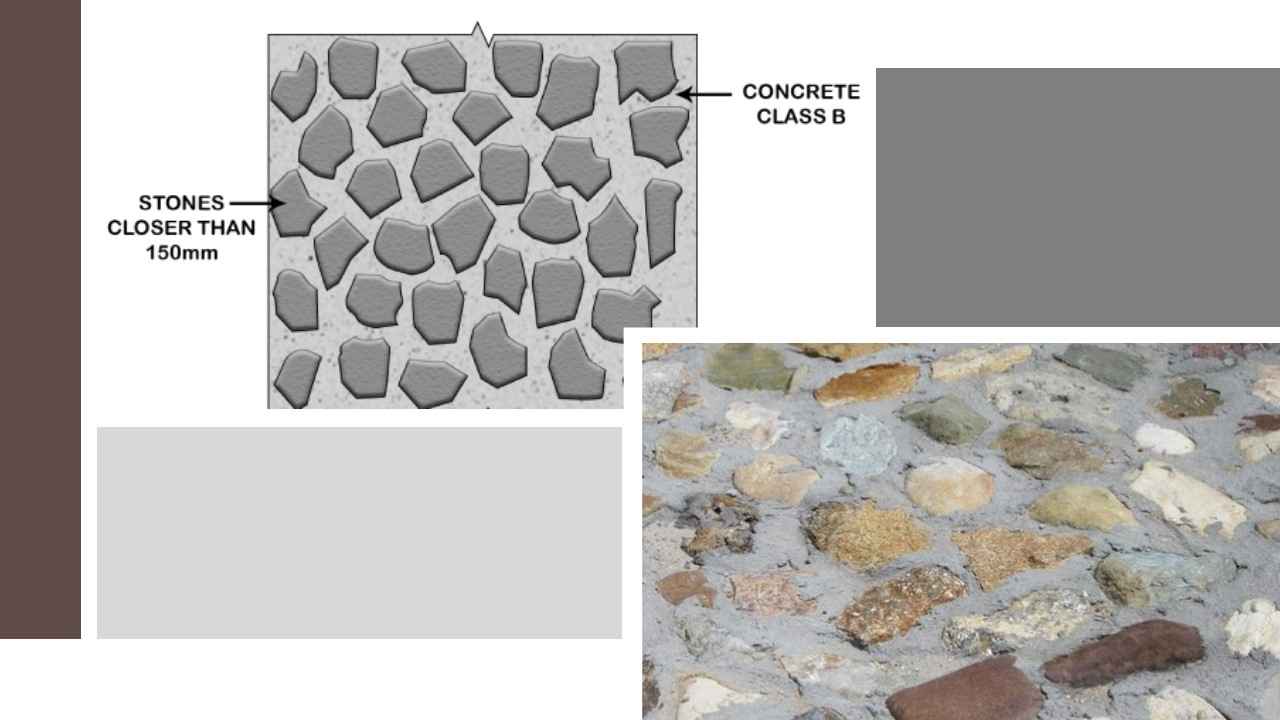

- Class B concrete, which includes huge rocks, is required for the plum concrete.

- Plums cannot take up more than a third of the space in the area where they are used. (i.e. 33%)

- The final purpose of the plum concrete and the necessary level of strength will establish the grade utilised in its production. However, the bare minimum is M20.

- Stone or plumbing fixtures can be no smaller than 150mm in some circumstances, with the maximum size being determined by the building's overall footprint.

- It is required that there be at least 150 millimetres of concrete all the way around each stone.

- The formwork for pouring the plum concrete must be steel plates or plywood.

- We recommend allowing 7-14 days for a cure.

Neither the middle nor the outermost layers of the concert plum exceeded a height of 900 millimetres.

Spaces deeper than 150 mm are not permitted in any one layer. As a percentage of the total, the concrete plum will not surpass 40%. For the best results, use a maximum 25mm aggregate size and an M10 concrete grade.

Plum will be made up of 100 kilos per square centimetre (or more) of crushing-strength black trap basalt. The compactness of plum concrete is 1650 kg/m3.

Concrete can easily be placed so as to mount all reinforcement methodically. The maximum size of coarse aggregate ought to be as large as possible, but should not be greater than one-quarter of its minimum thickness of this unit.

According to the IS code, the size 20 aggregates is optimum and suitable for most of the usual works, however there are variations on this guideline depending on the type of job being done.

40 mm or greater is also used if there are no constraints on the concrete's ability to flow to the portion.

Plum concrete should have a maximum size of 10 mm where reinforcement is present. In plain concrete work, plums larger than 150 mm and of roughly any appropriate size may be used up to a maximum limit of 20% volume of the concrete.

In any event, though, you can expect the plums to be scattered uniformly and to be at least 150 mm from the ground at their closest.

Read More:

Construction Procedure of Plum Concrete

- Delivering Plum Components is Step One. Workers can easily lift the boulders because of the stone size they contain.

- The Second Step: Cleaning and Leveling Surface Arrangement. Any soft soil that could result in a lack of bearing capacity must be removed and the surface well levelled and cleaned. After the land has been cleared of brush and debris, it is soaked with water in preparation for the placement of plum concrete.

The aim of this watering is to keep the concrete in perfect contact with the ground. As soon as the water has been sprinkled, the anti-termite chemical is sprayed to protect the building's base from being eaten away.

- Third, the spacing and expansion of Plum Concrete Boulders are placed on the ground in a series of layers with minimal gaps in between them, and concrete is pumped over the boulders in each layer, where it progressively fills the spaces between them.

After the concrete has been poured, the stones are returned to the surface and the process is repeated until the ideal level surface is accomplished, allowing for perfect tying.

- Fourth, let the Plum Concrete cure. At least a week must pass for the curing process to be successful. In order to maintain the concrete's moisture for an extended time after curing, jute bags are dispersed over the whole area.

If any dirt or clay is found on a boulder, it must be thoroughly cleaned before it can be used. Because of the weight of the entire structure, boulders need to be sturdy and reliable. In the event of a concrete scarcity, for financial reasons, or for any other reason, it may be necessary to purchase additional boulders.

Application of Plum Concrete

- The normal practice calls for plum concrete to be used as a footing base to prevent groundwater seepage.

- Plum Concrete can be exploited for large-scale construction projects like constructing bridge piers or concrete dams. Here, coarse particles of about 150 millimetres in size are used to make plum concrete.

- The first dam was built with plum concrete that employed plums of 150 mm in diameter and had a cement content of 177 Kg/m3.

- It was hypothesized that a more unified concrete mix of 150 MSA could be attained with relative ease using high-speed mixers of suitable capacity.

- As another example, let's say it's recommended that the pit under a machine's bed have a certain depth, but the hard stratum is just 3 meters below the surface.

- Whereas in the plan it was proposed that the bed's base may be 1.5 m deep.

- Plum concrete of thin ratio utilising 80mm -100 millimetre stones will be poured, pushed up to 1.5 m, and then typically planned raft, footings may be installed. This is because the foundation requires to be resting on the hard layers of soil.

Field Use of Plum Concrete

Subsequent to the footing and foundation, a level surface is achieved with the help of plump concrete. You can use it to save money on PCC if you need a sizable PCC thickness but it won't affect the performance. Its primary application is in bulk concreting projects, such as gravity dams, barriers, and side slopes.

For instance, if the area under a footing in a residential building is too shallow, plum concrete must be used.

I hope the blog provides you with a sound understanding of Plum Concrete and its applications.

Please feel free to like, share and comment.

Admin, gcelab.com

Please see our Pillar Post to know why we founded gcelab.com.

Read More:

Pooja

Founder at gcelab.com, Pooja is an Entrepreneur unlocking human potential. Working in the Principles of Lean Start-up, Pooja believes in Transparency and User Happiness the most. Pooja’s background in teaching gives her a sophisticated grasp on even the most tedious aspect of course building. She is passionate about people who believe that good is not enough.

Previous Post

Gable Roofs and Types of Gable of Roofs

Next Post