Packing Density of Aggregate: Maximizing Efficiency in Aggregate Packing

- By

- Pooja |

- June 10, 2023 |

- Civil Engineering, Construction,

Table of Contents

What is Packing Density of Aggregate?

Determination of Packing Density

What is Packing Density of Aggregate?

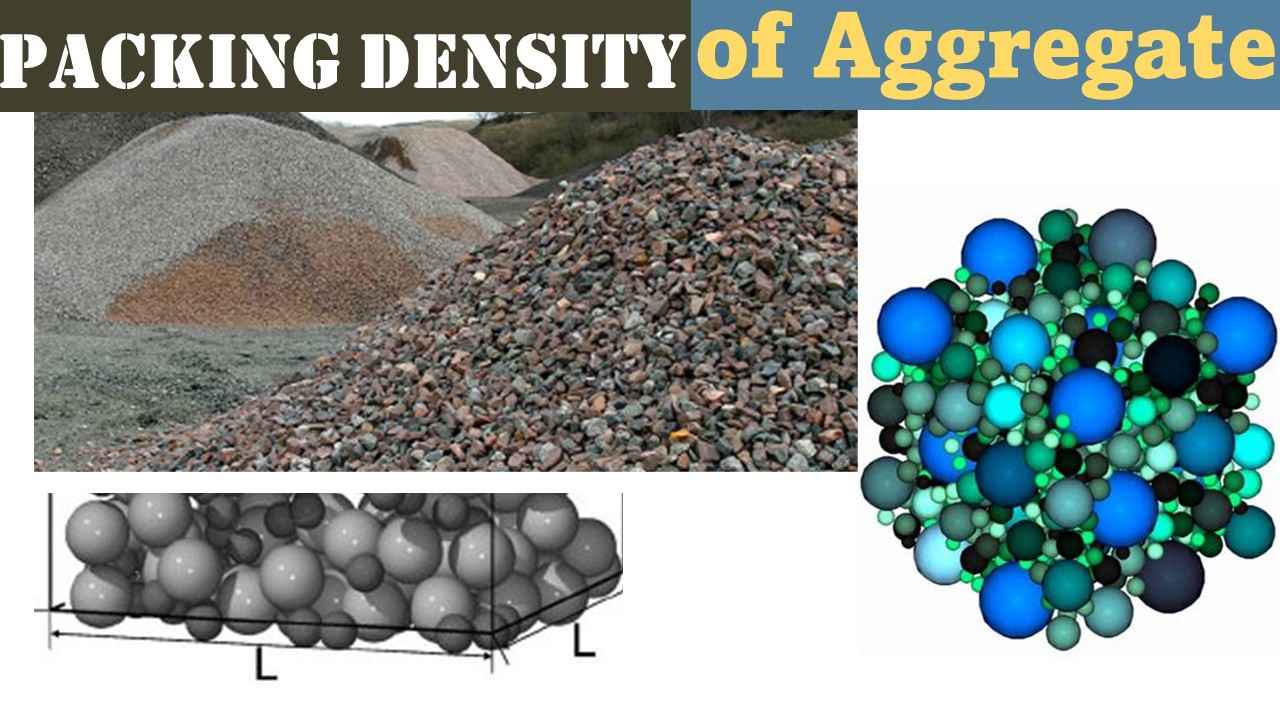

Particles' packing density, also known as packing degree, is the volume of solids in a given volume of particles, defined as the volume of solids minus the volume of voids. As a measure of how effectively aggregate fills a given volume, packing density is an essential topic in concrete technology. Packing more particles into a shared space reduces the amount of more expensive binder needed to fill in crevices and adhere the particles together.

The volume of solids that may be held within a particular volume of particles is referred to as the packing density of the particles. The packing density of particles is also frequently referred to as the packing degree. The volume in question can be determined by taking the volume of solids and subtracting it from the volume of voids. When it comes to the science of concrete, one of the most vital things to consider is the packing density of the aggregate.

This is the case due to the fact that packing density is a measurement of how effectively aggregate fills a particular volume.

When more particles are compressed into an allocated space, a lower amount of the more expensive binder that is necessary to fill in fissures and bond the particles together is required. This results in a reduction in the overall cost of the product.

Determination of Packing Density

Using an aggregate's maximum bulk density of mix in conjunction with the aggregate's specific gravity, we are able to compute the packing density of an individual aggregate. Because of this, we are able to express the packing density as a percentage of the aggregate's total volume or of the aggregate as a whole.

Packing Density can be calculated by multiplying Bulk Density by Weight Fraction and then dividing that number by Specific Gravity.

In addition to the aggregate parameters, the manner in which the material is compacted as well as the size of the container both have an effect on the packing density, which is also referred to as the packing degree.

Pouring the sample without doing anything else to it will result in a packing density that is lower than the packing density that could be attained by tapping the sample with a rod or vibrating the sample.

It has not been feasible to establish a correlation between the different packing densities that are produced by the various compaction techniques because it is dependent on the particle size, shape, and texture. This is because it is dependent on the particle size, shape, and texture.

Read More:

In point of fact, the density of crushed aggregate is likely to be lower than that of rounded material, whereas the density of aggregate that has been vibrated is likely to be higher. This difference in density can be attributed to the fact that crushed aggregate is more likely to be broken up into smaller pieces.

Dry packing, in which air is used, or wet packing, in which water or another liquid is used, could both be utilised for the goal of establishing the packing density.

Dry packing, in either the SSD state or oven-dry has been shown to be able to accurately predict the behaviour of particles in concrete that have been retained in the No. 200 sieve (i.e. 75 micron).

Dry packing is not a reliable predictor of the actual behaviour of very small particles (those that pass No. 200 mesh) when those particles are subjected to the wet conditions that are present in freshly mixed concrete. This is due to the strong influence of inter-particle interactions makes dry packing an unreliable predictor.

It has been suggested that water demand methods be utilised to conduct testing on particles with a size of less than 75 microns in order to establish the packing density of these particles. These tests would be conducted in order to determine the packing density of the elements. Fly ash, cement, and aggregates are all good examples of the types of particles that fall under this category.

In theory, concrete mixtures with higher packing densities of aggregates require less water and paste to obtain the same level of workability as those with lower packing densities of aggregates. This is due to the fact that a given volume of space may accommodate a greater number of particles.

Because cement is the most expensive significant component of concrete, and because cement paste causes shrinkage, heat development, and certain challenges with durability, the ideal type of concrete is one that satisfies all of the specifications while requiring the absolute minimum amount of cement feasible. Cement is the most expensive significant component of concrete, which explains why this is the case.

Sand and coarse material were mixed together and then intensively compressed to create the best concrete mix possible. This mix had the needed level of workability.

The primary goal of optimising concrete mixtures is to blend the aggregates in such a manner that they achieve a maximum or near-maximum packing degree while retaining their workability. This can be accomplished by mixing the aggregates in such a way that they are distributed evenly.

I hope the blog provides you with in-depth knowledge of the packing density of Concrete.

Please feel free to like, share and comment.

Admin, gcelab.com Please see our Pillar Post to know why we founded gcelab.com.

Read More:

Pooja

Founder at gcelab.com, Pooja is an Entrepreneur unlocking human potential. Working in the Principles of Lean Start-up, Pooja believes in Transparency and User Happiness the most. Pooja’s background in teaching gives her a sophisticated grasp on even the most tedious aspect of course building. She is passionate about people who believe that good is not enough.