What is Tunnel Boring Machine (TBM)? 9 Important Points

- By

- Pooja |

- October 09, 2021 |

- Tunnel Engineering,

Table of Contents

What is Tunnel Boring Machine?

How to operate a Tunnel Boring Machine?

How fast are Tunnel Boring Machines?

Why is a Tunnel Boring Machine so expensive?

Are tunnels safe in earthquakes?

Types of Tunnel Boring Machine (TBM)?

What is the main risk of Tunnel Boring Machines?

The ground condition where TBM are suitable to use?

Advantages and disadvantages of TBM?

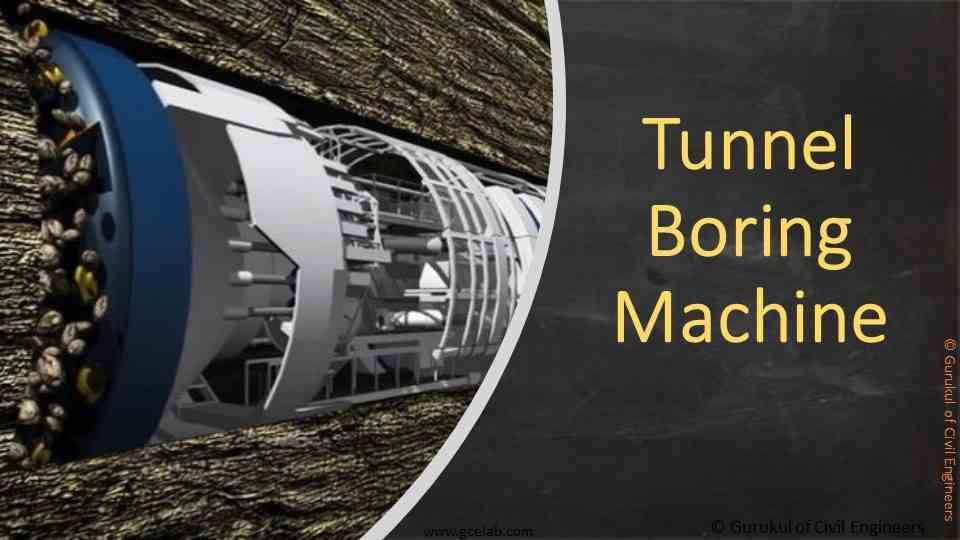

What is Tunnel Boring Machine?

A tunnel boring machine (TBM), commonly described as a mole, is a machine that excavates circular-shaped tunnels through various soil and rock strata. “They can pierce hard rock, sand, and practically any other material. To date, tunnel diameters have ranged from a meter (done with micro-TBMs) to nearly 16 meters.

Horizontal steering drilling or Trenchless construction are normally recommended to use instead of TBMs for tunnels less than a meter in diameter. Drilling and blasting operations in rock and traditional hand mining in soil are both replaced by Tunnel Boring machines.

The TBMs have the advantage of causing minimal ground disturbance and providing a smooth edges tunnel wall. This lowers the expense of tunnel lining the makes it appropriate for usage in densely populated urban areas. The initial expenses of using TBM are very high. TBMs are both costly to build and difficult to move.

However, as newly tunnels come with longer life and fewer maintenance liabilities, the overall construction cost of tunnels with boring machines decreases. This is due to the fact that tunnelling using TBMs is far more efficient and construction duration also reduces significantly.

How to operate a Tunnel Boring Machine?

Vibrations, Heave and Subsidence must be minimized in order to eliminate any harm to the structures. With an outside dia of 12 meters and approx length of 95 meters, the S-442 is a traditional EPB machine. The tunnelling machine separates the material from the tunnel phasing with its spinning cutting wheels.

The material is subsequently transferred to the conveyer belt with the hydraulic cylinders continually pressing the machine forward. The lining segments are placed beneath the shield's skin for protection.

How fast are Tunnel Boring Machines?

Each machine functions as a self-contained subterranean factory that, in addition to excavating the tunnel, will line it with concrete wall segments and cement them into place as it advances at a rate of about 15 meters per day.

Read More:

What is the Function of Bridge Foundation or Pier and its Types? 5 Important Points

What is Tunnel Engineering and Tunnel Design? 7 Important Points

Why is a Tunnel Boring Machine so expensive?

Fundamentally, excavating a tunnel involves moving a huge amount of mass through a highly limited region (so large excavation machines are impractical). This is why, if at all possible, "cut and cover" tunnelling is preferred. Also digging through complex geology for which you'll need to give physical support and for which you can only sample/model imprecisely beforehand.

Initially, the multi-million-dollar tunnel boring machines, such as those used to dig the tunnel, are frequently considered as expensive and therefore abandoned, but given that they are essentially designed and built for a specific project, and the amount of time (fast speed of execution) it would take to dismantle, it makes economic sense to use TBMs.

Are tunnels safe in earthquakes?

It is dependent on the tunnel types. A reinforced concrete tunnel, such as a road drainage tunnel or a railroad tunnel, is quite likely to be safe. A dirt tunnel is unlikely to be as secure. However, you must be mindful of what is at both tunnel entrances in addition to the tunnel itself.

If the material is uncompacted dirt, sand, or even a mound of rocks, an earthquake may dislodge enough material to block the tunnel entrance and/or exit, making it impossible to get out.

Types of Tunnel Boring Machine (TBM)?

Main Beam

A TBM with a Main Beam is ideal for breaking up hard rock. The Main Beam machine, according to the Robbins firm, is the way to go if you want to drill through hard rock in the quickest amount of time feasible. The machine operates by forcing disc cutters into the rock while the cutter-head rotates, and the cutter-head is the same size as the tunnel diameter.

The machine can easily advance due to the combination of high force and rotating chipping away at the rock.

Double Shield TBM

Double Shield TBM was developed by the Robbins Company way back in 1972 to safely operate tunnel projects passing through ruptured rock and it was something that’s never done earlier. Double Shield TBM comprises of a rotating cutter-head, affixed to the cutter-head support, and followed up by three shields known as gripper shield, tail shield, and telescopic shield.

Single Shield TBM

TBMs with a single shield are appropriate for projects that require vast portions of fractured ground to be drilled through. Because fractured earth poses a safety concern to any boring project, it's critical to employ a single shield boring machine, which includes a shield that shields construction operatives from broken rocks until the tunnel lining is placed securely.

Earth Pressure Balance

Balance or Earth Pressure Balance (EPB) is made to operate in soft ground conditions. EPB comes with an articulated shield and its works pretty well against entering water pressure. Along with this it monitors & controls the pressure inside the cutter-head to achieve balance.

Read More:

How to learn STAAD Pro? 7 Important Points

How do you answer tell me about yourself in an interview? 5 Important Points

What is the main risk of Tunnel Boring Machines?

The primary geological concerns that affect the efficiency and safety of a tunnel construction with TBM are soft fractured rock masses, fault fractured zones, water inrush, water-bearing structures, collapse, boulder falling, surrounding rock deformation and rock-burst.

The ground condition where TBM are suitable to use?

TBMs with a single shield are appropriate for projects that require vast portions of fractured ground to be drilled through. Because fractured earth poses a safety concern to the project.

Advantages and disadvantages of TBM?

Advantages of TBM

- Allows tunnelling through soft, damp, or unstable ground at a faster speed and with safety.

- Suitable for use in areas where water pressure is high

- Ground settling is reduced, resulting in a smooth tunnel wall. This reduces the lining cost and makes it economical to deploy in densely populated areas.

Disadvantages of TBM

- The upfront capital expenditure is the most significant disadvantage. TBMs are costly to build, difficult to move, and require extensive backup systems and electricity.

- Large stones and rocks can make driving difficult.

I hope this blog offers you adequate information about Tunnel Boring Machine (TBM). Please feel free to like, share and comment about it.

Admin, gcelab.com Please see our Pillar Post to know why we founded gcelab.com.

Pooja

Founder at gcelab.com, Pooja is an Entrepreneur unlocking human potential. Working in the Principles of Lean Start-up, Pooja believes in Transparency and User Happiness the most. Pooja’s background in teaching gives her a sophisticated grasp on even the most tedious aspect of course building. She is passionate about people who believe that good is not enough.