Triaxial Test of Soil Sample

- By

- Pooja |

- June 04, 2022 |

- Civil Engineering, Geotechnical Engineering,

Table of Contents

What is a triaxial test of a soil sample?

What is the need for a triaxial test?

The procedure of the triaxial experiment

Apparatus name of triaxial test

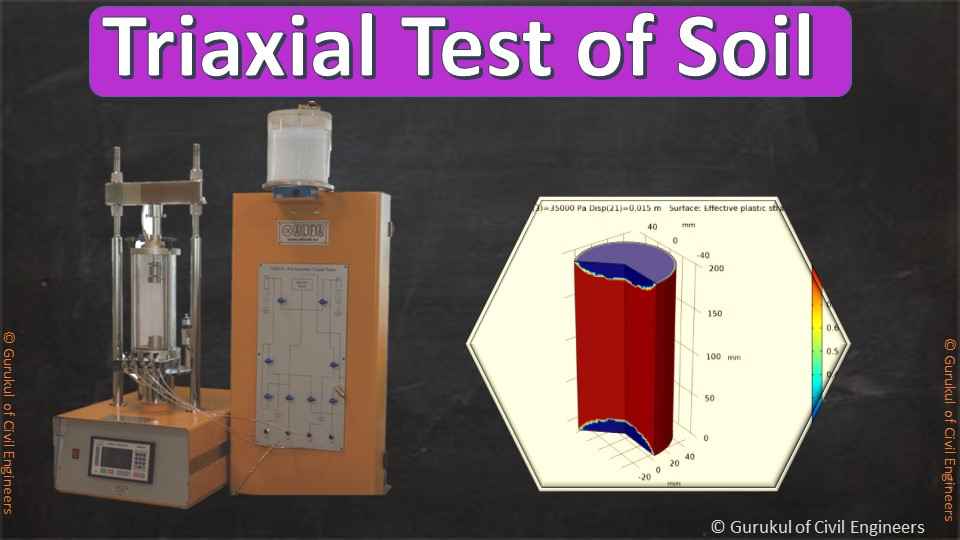

Motorized Triaxial Shear Test Apparatus - (SICSTSTA-01)

What is a triaxial test of a soil sample?

Triaxial testing is a sort of shear test for solid materials that are performed with confining pressures on all sides of the specimen. To imitate strains from surrounding soil materials, confining pressures are generated in a fluid chamber.

The behaviour of materials in place can then be better understood. This technique can be used to test rocks, powders, and construction materials, however, this blog article will focus on soil triaxial shear testing.

What is the need for a triaxial test?

Triaxial testing determines the mechanical behaviour of soil materials, ensuring that the soils supporting the structures are suitable for the specified application and their continuous performance.

Soil triaxial shear testing is more than just one test. This blog will go through three alternative test procedures, each with various needs based on soil types and specimen attributes.

The procedure of the triaxial experiment

The load frame holds the assembled test cell, which contains the prepared specimen and water. The triaxial control panel's air and water lines are connected, and the load and deformation measurement instruments are placed and zeroed. Triaxial tests are divided into three phases, each with its own set of variations.

Comprehensive reading and knowledge of the specific test method utilized are required for successful testing.

Saturation is the process of filling all cavities in the soil samples, as well as porous stones and drain lines, with water without causing undue disruption. The steps necessary for the various test methods vary significantly, but the majority involve de-aired water produced by a deaeration unit in conjunction with back pressure saturation.

Backpressure, or extra pressure applied to the specimen's pore-water, compresses the sample's air and forces it into solution, raising saturation.

Consolidation happens when the fluid in the test cell is confined by restricting pressures. Because drainage is not allowed in the UU test, a completely saturated specimen cannot consolidate due to confining stresses.

If evaluated at different confining pressures, partially saturated samples can consolidate and have varied strengths. A volume change of the sample will occur for CU and CD specimens drained during consolidation.

The strain rate employed during axial loading is determined by how long it takes for the consolidation to achieve equilibrium. The specimen is axially loaded during the shear phase of the test. The rate of loading for the UU (or "quick") test is set between 0.3% and 1% per minute, resulting in the failure in around 15 minutes.

Strain rates for CU and CD tests must be calculated using numbers from each consolidation phase, and they are substantially lower. For these procedures, total test times could be days or weeks.

Conclusion

Each test's final computations and data reporting adhere to the standards of the specific test methodologies. Triaxial testing is clearly not a one-size-fits-all approach. Depending on the specimen type and methodology used, each standard has several variations.

Apparatus name of triaxial test

Motorized Triaxial Shear Test Apparatus - (SICSTSTA-01)

To determine the triaxial shear strength of 28mm diameter soil specimens. The sample's length to diameter ratio is 1:2. Specification: One loading unit with a capacity of 5 tonnes for single cell mounting. A motorised load frame is included.

One dial gauge bracket is included with the loading unit. One stationary Triaxial Cell for a 38 mm dia specimen. Assembly for Lateral Pressure. Complete with foot pump and rubber hose for 0-10kg/cm sq. For strain measurement, one 0.01 mm X 25 mm dial gauge is used. One high-sensitivity Proving Ring with a capacity of 200/250 kg and a carrying case.

Accessories: Proving Ring with high sensitivity, 1000 kg capacity, calibration report, and packing case

Important Features Apparatus for Triaxial Shear Testing (Motorised) Single Speed: As before, but with a motorised load frame included. This equipment includes a bench mounting type motorised load frame rated at 5000 kg-f with a constant rate of strain of 1.25 mm/min. 230 Volts AC is recommended for use.

Apparatus for Triaxial Shear Testing (Motorised) Universal 3 Speed Apparatus for Triaxial Shear (Motorised) 6 Speed: For evaluating the triaxial shear strength of 38 mm, 75 mm, and 100 mm soil specimens.

It includes One 5000 kg-f motorized load frame with six constant strain rates, yielding the following strain rates. 1.25, 0.25, 0.05, 0.01,0.002,0.0004 mm/min. A dial gauge bracket is included with the load frame.

Triaxial Universal Cell 10 kg/cm.sq. One lateral pressure assembly ranging from 0 to 10 kg/cm.sq, complete with a foot a pump and a rubber hose. One 1000 kilograms capacity high sensitivity Proving Ring 0.01 X 25 mm strain dial gauge 230 Volts AC is recommended for use.

I hope this post provides you with a good understanding of Triaxial Test of Soil Sample. Please feel free to like, comment and share it.

Admin, gcelab.com Please see our Pillar Post to know why we founded gcelab.com.

Read More:

Pooja

Founder at gcelab.com, Pooja is an Entrepreneur unlocking human potential. Working in the Principles of Lean Start-up, Pooja believes in Transparency and User Happiness the most. Pooja’s background in teaching gives her a sophisticated grasp on even the most tedious aspect of course building. She is passionate about people who believe that good is not enough.

Previous Post

What is Urban Regeneration and Why It is Important?

Next Post