What is Bracing System in Structure?

- By

- Pooja |

- January 22, 2022 |

- Civil Engineering, Bridge Engineering, Building/ Structure Engineering,

Table of Contents

What are the types of Bracing systems?

How does diagonal bracing work?

What is a Bracing System?

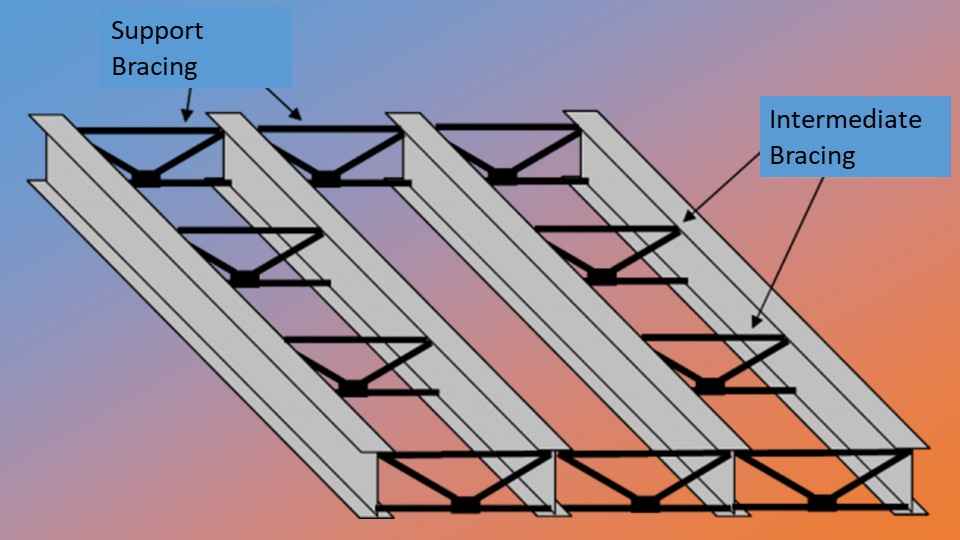

A bridge's bracing system is a subsidiary but crucial component. A bracing system helps to stabilise main girders during the construction time, distribute load effects, and limit compression flanges that could otherwise buckle laterally.

What is the function of the Bracing System?

Bracing that runs vertically. Vertical bracing (between column lines) provides load pathways that convey horizontal forces to the ground level while also providing lateral stability. “Bracing on the horizontal plane.

At each floor level, horizontal bracing (usually provided by floor plate action) provides a load path for horizontal forces (mostly from the perimeter columns owing to wind) to be transferred to the vertical bracing planes.

What are the types of Bracing systems?

Sway Bracing

Sway braces are used to regulate vibration, absorb shock loads, guide or constrain pipe movement caused by thermal expansion, and brace a pipeline against sway. In both stress and compression modes, they contain springs that provide a restraining force.

Bracings are particularly important in steel structures to resist lateral forces and increase the rigidity of the steel frame. The structure will become uncertain as a result of bracing. However, it stiffens the structure and aids in its resistance to sway. Straight members, bracings solely carry axial forces.

Steel Bracing

The basic structural members of a typical RCC (reinforced cement concrete) construction are the beam, column, and slab, which are also the main structural components of a steel structure. Steel is utilised in conjunction with concrete in RCC structures, making them heavier than steel structures.

Sections in RCC structures will be heavier than steel structures for a given load situation. When a conventional single-bay frame is subjected to lateral load, it sways. The sway increases as the structure's height rise. Bracing is offered to reduce sway.

Unbraced frames are those without bracings, while braced frames are those with bracings. The structure is stiffened via bracing. Only axial load is carried by bracing, which might be compression or tension.

The static internal indeterminacy, on the other hand, grows as the kinematic indeterminacy diminishes.

Beam Bracing

A lean-on system braces a beam or column that relies on nearby structural elements for support. Lean-on systems are made up of structural members that are coupled or linked together in such a way that buckling one part requires nearby others to buckle with the same lateral displacement.

Vertical Bracing

Bracing is provided between column lines in the vertical planes, which provides load channels for transferring horizontal forces to the ground level. This system is designed to distribute horizontal loads to the footings while still withstanding the structure's overall sway.

Read More:

- What is Earthquake Resistant Building | Structure? 8 Important Points

- How to Prepare a Structural Drawing?

How does diagonal bracing work?

Let’s consider an example as described below:

The structure of the building is made of steel. The building's plane layout is built with three cores: 32 frame columns, eight on each side of the exterior cube, and a 6 m spacing between columns.

The internal tube is made up of 20 columns and is joined to the outside tube by steel beams, with a distance of 14.6 metres between them. The core tube is made up of four columns, each one is larger than the others.

Cantilever trusses are also installed at the top of the structure. Steel–concrete composite slabs are used for the floor slabs. Cross bracing is a mechanism used in construction to reinforce building structures where diagonal supports overlap.

The most common form of cross bracing is an X-shaped arrangement of two diagonal supports. One brace will be tensed while the other is compressed when subjected to lateral stress (such as wind or seismic activity).

Steel cables can be utilised in steel construction because of their high tension resistance (although they cannot take any load in compression). Bridge (side) supports and structural foundations are two common applications for cross bracing.

This construction style maximises the weight of the load that a structure can support. The cross-beam joining arches is also a sort of cross brace used to enhance strength in the building of mining tunnels. They're frequently tubular, having clips or perforations for screw fastening on the ends. They act as a stiffening element for a design's stability.

This brace could either be a board or a regular cross-section timber cross-beam. Cross bracing can be seen in settings like flooring, where cross braces are used to prevent movement between floor joists. It's also often used in shipbuilding to withstand strong winds and adverse weather.

How does Roof Bracing Work?

At the rafter level, longitudinal and diagonal bracing should be offered (this may be excluded where rigid panels are used, e.g. plywood or chipboard that are fixed to each trussed rafter with galvanised round wire nails.

Small gaps, like two trussed rafters between bracing, are permissible in the midst of a fully braced roof.

Longitudinal bracing must run along the length of the roof, and the party walls. It should authorize diagonal bracing to flow through it. Each roof shall have at least four diagonal bracings; when the braces cross in thin fronted or mono-pitched roofs, the junction.

When the span is greater than 8 metres. Bracing should be developed for mono-pitch roofs and duo-pitch roofs for 11m span or more. It should be roughly 45° for the web members.

Two diagonal members create a V-shape stretch downwards from the top corners of the horizontal members and meet at the lower horizontal members at the centre point.

Both approaches can drastically reduce the compression brace's buckling capacity down below the tension yield capability of the brace. This means that once the braces have reached their resistance capability, the load must be challenged in the horizontal member's bending.

Innovative Bracing System in Structure

An innovative bracing system in a structure can improve its stability, safety, and durability by distributing loads more evenly and effectively. Here are some examples of innovative bracing systems in structures:

Buckling-restrained braces (BRBs):

Buckling-restrained braces (BRBs) are designed to provide reliable and predictable behaviour during earthquakes by resisting lateral loads through a controlled buckling process. They are made of steel and feature a restraining element that prevents them from buckling too far.

Self-Centring braces:

These braces are designed to bring a building back to its original position after an earthquake. They rely on a combination of steel and rubber components that allow them to flex and bend during an earthquake while still maintaining their strength.

Diagonalized bracing:

This type of bracing system involves diagonal braces that are placed in such a way that they intersect at a central point. This allows for greater load distribution and improved stability, especially in taller structures.

Damping braces:

Damping braces use a combination of steel and special materials that absorb and dissipate the energy generated by lateral loads, such as those caused by wind or earthquakes. This helps to reduce the impact of these loads on the overall structure and can improve its safety and durability.

Shape memory alloy braces:

These braces are made of a type of metal that can "remember" its original shape when subjected to certain conditions, such as high temperatures or mechanical stress. This allows them to bend and flex without losing their strength, making them ideal for use in earthquake-resistant structures.

Innovative bracing systems in structures involve using advanced materials, technologies, and design elements that improve the stability, safety, and durability of the structure in the face of various types of external loads and forces.

I hope the above blog provides you with in-depth knowledge of the Bracing System in Structure.

Please feel free to like, share and comment.

Read More:

- What is Honeycombing of Concrete? Prevention and Repair: 8 Important Points

- Pre-stressed Concrete, Pre-tensioning and Post-tensioning: 3 Important Points

Pooja

Founder at gcelab.com, Pooja is an Entrepreneur unlocking human potential. Working in the Principles of Lean Start-up, Pooja believes in Transparency and User Happiness the most. Pooja’s background in teaching gives her a sophisticated grasp on even the most tedious aspect of course building. She is passionate about people who believe that good is not enough.

Previous Post

How to Prepare a Structural Drawing?

Next Post