The Evolution of 3D Printing in Road Construction

- By

- Pooja |

- December 26, 2023 |

- Civil Engineering, Innovation,

Table of Contents

The Genesis of 3D Printing in Road Construction:

The Advantages of 3D Printing in Road Construction:

Speed, accuracy and Efficiency:

The Pioneers and Success Stories:

The Future of 3D Printing in Road Construction:

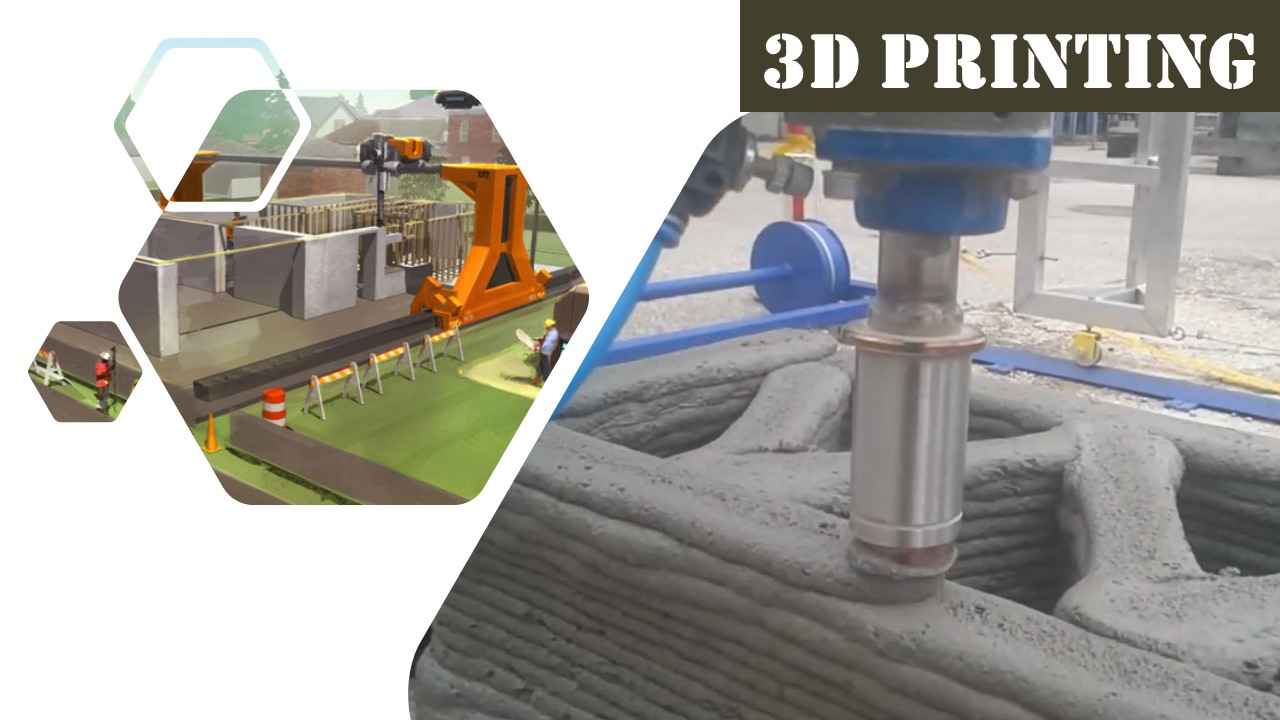

Innovation in the construction industry has seen remarkable advancements over the years, with technology playing a pivotal role in transforming the way we build infrastructure. One such groundbreaking technology that has been making waves in the construction sector is 3D printing.

While 3D printing has gained recognition in various fields, from healthcare to aerospace, it's also quietly transforming the way we build roads. This blog delves into the fascinating evolution of 3D printing in highway construction, exploring its benefits, challenges, and the exciting future it holds.

The Genesis of 3D Printing in Road Construction:

The concept of 3D printing in road construction may seem like a futuristic idea, but it has been in development for over a decade. The early experiments in this field aimed to reduce the environmental impact of road construction while also increasing efficiency.

Traditional methods often involve extensive excavation, resource consumption, and waste generation. 3D printing, with its potential to streamline the process, promised a more sustainable alternative.

The Advantages of 3D Printing in Road Construction:

Sustainability:

Traditional road construction methods can be resource-intensive and generate a significant amount of waste. In contrast, 3D printing can be more sustainable by reducing material waste and energy consumption. It allows for the precise deposition of construction materials, minimizing excess usage.

Speed, accuracy and Efficiency:

3D printing expertise has the potential to expedite road construction significantly. The process is automated, reducing the reliance on manual labor and shortening project timelines.

Design Flexibility:

3D printing facilitates the creation of intricate and customized road designs. This flexibility can lead to safer and more efficient road networks, tailored to specific geographical and traffic needs.

Reduced Maintenance:

Properly constructed 3D-printed roads can offer enhanced durability, requiring less maintenance over their lifespan.

Challenges and Hurdles:

While the advantages are clear, the acceptance of 3D printing in road construction has not been without its share of challenges:

Regulatory Framework:

Introducing a technology as novel as 3D printing into a heavily regulated industry like construction presents complex legal and regulatory issues. Adapting existing construction standards and regulations to accommodate this technology is an ongoing challenge.

Material Quality:

Ensuring that the materials used in 3D printing are of high quality and meet the necessary safety standards is crucial. Materials must also be compatible with the 3D printing process to avoid structural issues.

Costs:

Initial setup costs for 3D printing technology and machinery can be high. However, these costs are often offset by savings in material and labor costs over the long term.

Scaling Up:

Although 3D printing has demonstrated its worth in smaller pilot projects, scaling up for large-scale road construction remains a significant challenge. Engineers and developers need to work on systems capable of printing roads that extend over several miles.

Read More:

The Pioneers and Success Stories:

Several countries and organizations have been at the forefront of developing 3D printing technology for road construction. Notable examples include:

The Netherlands:

The Dutch are pioneering 3D-printed bridges and cycle paths. Their innovative approach to infrastructure construction has garnered international attention.

China:

China is actively exploring 3D printing technology for both residential and road construction. The country has already successfully implemented 3D-printed bus stops and pedestrian bridges.

United States:

The United States is not far behind in the race to adopt 3D printing in road construction. Research institutions, government bodies, and private companies are collaborating on various projects to explore the potential of this technology.

Dubai:

The Dubai government has expressed a keen interest in 3D printing for road construction and is actively supporting projects that aim to advance the technology.

The Future of 3D Printing in Road Construction:

The evolution of 3D printing in road construction is an ongoing journey, and the future looks promising. Here are some exciting possibilities:

Smart Roads:

3D-printed roads can incorporate embedded sensors and other technologies that make them "smart." These roads can provide real-time traffic information, weather conditions, and even perform self-repairs.

Customization:

With 3D printing, roads can be tailored to specific geographic features and climate conditions. This will lead to more durable and resilient infrastructure.

Eco-friendly Materials:

Research is ongoing to develop eco-friendly construction materials compatible with 3D printing technology, further reducing the carbon footprint of road construction.

Mass Production:

As technology advances and costs decrease, 3D-printed roads could become a common sight, transforming the way we build and maintain our transportation networks.

Global Expansion:

More countries are likely to adopt 3D printing in road construction, leading to increased international collaboration and knowledge-sharing.

Conclusion:

The evolution of 3D printing in road construction represents a significant leap forward in how we build and maintain infrastructure. While there are challenges to overcome, the benefits in terms of sustainability, efficiency, and flexibility are too compelling to ignore. As technology continues to advance, we can expect to see more 3D-printed roads and innovative solutions that not only improve transportation networks but also contribute to a more sustainable and strong future. The journey is just beginning, and the road ahead is filled with exciting possibilities.

Please feel free to like, share and comment.

Admin, gcelab.com Please see our Pillar Post to know why we founded gcelab.com.

Read More:

Pooja

Founder at gcelab.com, Pooja is an Entrepreneur unlocking human potential. Working in the Principles of Lean Start-up, Pooja believes in Transparency and User Happiness the most. Pooja’s background in teaching gives her a sophisticated grasp on even the most tedious aspect of course building. She is passionate about people who believe that good is not enough.